How Green Vault Systems' Equipment Helped Phat Panda Increase Production Capacity and Improve Quality

A Case Study on the Benefits of Purpose-Built, Tailored Cannabis Processing Solutions

In a crowded and competitive marketplace, cannabis companies need to stay ahead of the curve to succeed. This means leveraging the latest technologies to increase efficiency, improve product quality, and ultimately win over customers. One company that understands this is Phat Panda, a premier cannabis grower and processor based in Washington State.

By partnering with Green Vault Systems (GVS), a leading manufacturer of cannabis weighing and packaging equipment, Phat Panda has been able to scale its operations, solve production challenges, and expand its business.

In this case study, we’ll examine how GVS’s equipment helped Phat Panda achieve these goals, and why other cannabis companies should take note.

Share This:

Founded in 2014 by Robert and Katrina McKinley, Phat Panda started as a 30-member team and has now grown to more than 550 employees. Driven by a desire to inspire and innovate within the cannabis industry, Phat Panda blends the most advanced growing techniques with state-of-the-art technology to provide the best cannabis products to both seasoned consumers and new customers.

Since establishing itself in Washington, Phat Panda has expanded into other states, including California and Massachusetts. The company’s exponential growth mirrors that of the cannabis industry at large, with adult-use marijuana sales expected to skyrocket to more than $50 billion by 2026, according to MJ Biz Daily. The publication says that this sales growth spurt can be attributed to the opening of new markets, as the country continues to tilt towards full legalization.

As the projections demonstrate, the cannabis industry is booming. As such, companies like Phat Panda are constantly facing new challenges as they strive to keep pace with the market’s rapid growth. Some of these challenges include:

With its stellar reputation for producing high-quality products, the company needed to improve scaling efficiency due to increasing demand. Phat Panda found its existing equipment unable to keep pace with its growth. To remain competitive, the company needed to find a solution that would allow it to scale operations while maintaining the quality of its products.

Tyler Miller, Phat Panda Director of Facilities, explains the challenges the company faced with a competitor’s equipment before switching to Green Vault Systems’ equipment.

“Making the change to Green Vault Systems increased our overall efficiency and output,” Tyler says, adding that the repairs for the competitor’s equipment were also difficult, resulting in considerable downtime for Phat Panda.

And that creates a problem when it comes to Phat Panda’s main concern:

“Efficiency. That’s one of the biggest keys with our company in particular; we have a high amount of volume that goes out,” Tyler says. “So the scaling requirements are at an all-time high. We’re always trying to pump out as much product as humanly possible.”

To address the challenges of scaling up production, Phat Panda turned to Green Vault Systems, who worked closely with Phat Panda to design and implement an equipment solution that would meet the company’s specific needs.

Green Vault Systems’ equipment has helped Phat Panda significantly increase its production capacity and improve the quality of its products. The tailored solution designed by Green Vault Systems has allowed Phat Panda to streamline its production processes, resulting in increased overall production capacity.

The equipment is also gentle on the product and easy to clean and calibrate, making it intuitive for operators to use. Green Vault Systems’ commitment to customer service and support has helped Phat Panda maintain its focus on quality and craft, even as it scales operations to meet the growing demand for its products.

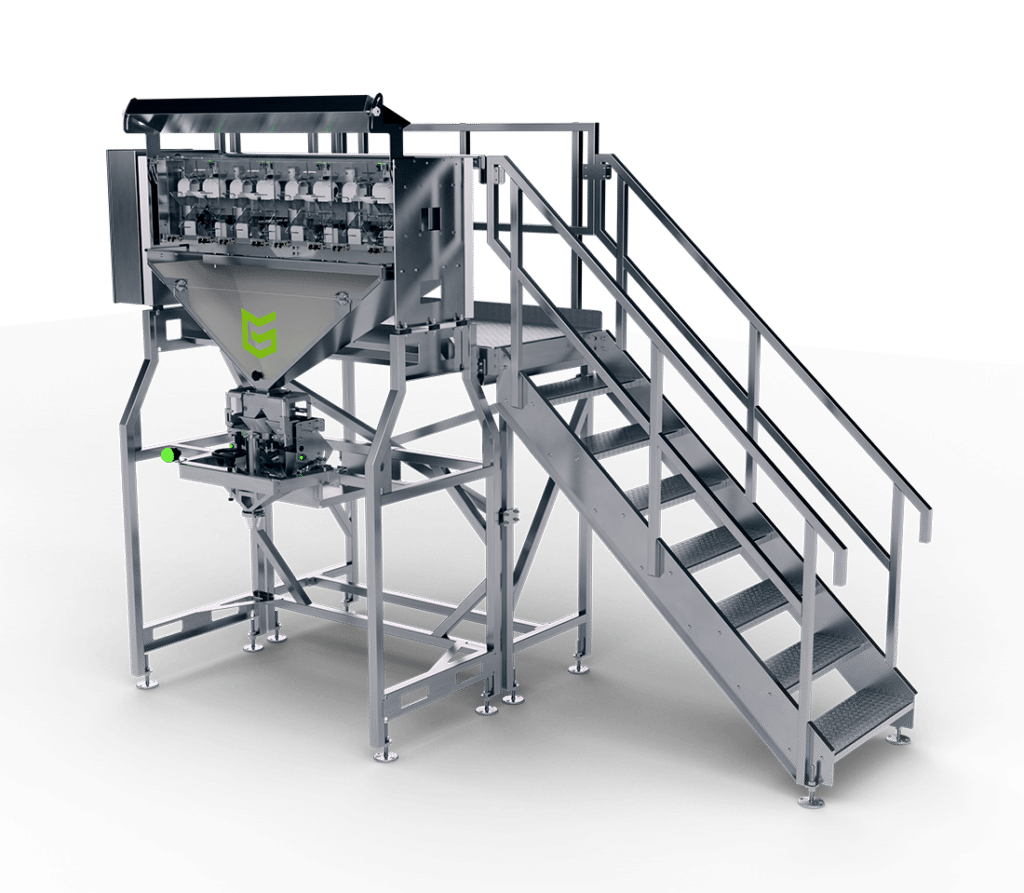

The Precision Batcher, designed specifically for cannabis by Green Vault Systems, is a high-speed, precision batching system that can accurately measure and dispense dried cannabis flower, at a high volume. Green Vault Systems designed the equipment to be easy to use and customizable to meet the specific needs of each customer.

Using GVS-patented Air Kush technology, the Precision Batcher smoothly and delicately moves the flower without causing damage, resulting in the highest-quality final product. At Phat Panda, cannabis cultivation is an art form, and every step of the process is taken with great care. That’s why Air Kush is a true game-changer. Unlike other manufacturers that rely on vibration to move dried flower along the packaging equipment, Air Kush uses tender puffs of air.

This meticulously controlled airflow ensures that the delicate trichomes of the cannabis plant are not compromised in the process, making Air Kush even more delicate than traditional hand-packing methods. It’s like a soft whisper, carefully guiding each precious bud along the line with the utmost tenderness.

Thanks to Air Kush, Phat Panda is able to produce some of the most exquisite strains of cannabis, boasting unparalleled flavor, aroma, and potency. It’s a true testament to the power of Green Vault Systems and their Air Kush technology, which not only enhances the natural beauty of Phat Panda’s plants but also ensures the highest level of quality and care in the production process.

The Precision Batcher is a critical component of Green Vault Systems’ equipment solutions and has helped many cannabis growers and processors improve their production capacity and product quality. For Phat Panda, Tyler says the Precision Batcher sparked a newfound scalability through it’s intuitive design:

“The GVS Precision Batcher is simple and easy to use,” says Tyler. “Most people can look at it and immediately understand what it does and how to use it without a mechanical background. That’s part of why I was sold on the Precision Batcher as soon as I saw it.”

For Phat Panda, the Precision Batcher:

What’s more, Green Vault Systems’ equipment has allowed Phat Panda to significantly increase its production capacity.

“Also, because of the smaller footprint compared to what we used before, we can operate two machines simultaneously, so we nearly tripled our output of scaled material,” Tyler says. “We were putting out 200-300 packages an hour before, but with GVS we now average 600 packages an hour.” The increased efficiency and production capacity have allowed Phat Panda to meet the growing demand for its products and expand its business.

Phat Panda faced daily weighing accuracy issues and limitations with its multi-head equipment. To solve this problem, Phat Panda partnered with Green Vault Systems and implemented their Precision Batcher. The GVS Precision Batcher vastly improved weighing accuracy and reduced variability, giving Phat Panda greater predictability of flower package weights. The improvement not only helped Phat Panda increase efficiency and reduce costs, but it also ensured regulatory compliance.

Phat Panda also faced a challenge with its multi-head equipment because the opening dimension of its jars didn’t align with the unit dispenser. However, with the flexibility provided by the Precision Batcher regarding packaging, and the quick change-over between products, Phat Panda was able to significantly improve this issue and streamline its processes.

“The Precision Batcher has allowed us to run reports from the machines and keep a running log of what we did and who was on the machine that day,” says Tyler. This feature helped Phat Panda improve their production processes and ensure consistency in their packaging, which allowed them to increase their efficiency and profitability.

Overall, the Precision Batcher from Green Vault Systems has helped Phat Panda overcome their packaging challenges and achieve significant improvements in their processes.

In the rapidly-growing cannabis industry, relationships are key. That’s why Phat Panda was so thrilled to find out that the team at Green Vault Systems brings so much more to the table than mere mechanical expertise.

“The team of individuals that own and operate Green Vault Systems are an absolute joy and pleasure to work with. They are extremely knowledgeable. And they are responsive.” Contrasting Green Vault Systems’ responsiveness with other companies in the industry, Tyler says that “when you contact some companies with questions or support requests, you’ll often wait up to three days for a response. It’s very challenging. You really have to hammer people. That’s not the case with GVS. They are always available and responsive. And they’re personable.”

Phat Panda’s partnership with Green Vault Systems has not only enabled them to scale up their operations but also maintain the quality and craft they have always been known for. The impact of Green Vault Systems’ equipment on Phat Panda’s employees has been significant, with the reduction in operator fatigue and the ease of use of the equipment.

As Tyler from Phat Panda emphasizes, maintaining quality and craft is crucial even as the cannabis industry continues to grow rapidly. With Green Vault Systems’ equipment, Phat Panda can efficiently meet the growing demand for their products while still maintaining their focus on quality. Green Vault Systems’ commitment to providing customized solutions and exceptional customer service has made them a reliable partner in the cannabis industry.

As the cannabis industry continues to grow, it’s clear that companies like Phat Panda need to find innovative solutions to scale up production while maintaining product quality. Green Vault Systems’ customized equipment solutions have helped Phat Panda address the challenges of growth and improve overall production capacity.

Green Vault Systems’ equipment solutions are designed to be intuitive, efficient, and customizable to meet the specific needs of each customer. From the Precision Batcher to the Air Kush technology, Green Vault Systems has helped many cannabis growers and processors improve their production capacity and product quality.

The need for innovative, purpose-built equipment solutions in the cannabis industry will only increase, and Green Vault Systems is leading the charge with its cutting-edge equipment and unparalleled customer service. If you’re a cannabis grower or processor looking to take your operation to the next level, contact Green Vault Systems today and experience the difference for yourself.

Discover why Green Vault Systems is the leading manufacturer of cannabis processing and extraction equipment. Contact us today and experience the difference for yourself.

Products

About

Contact Us

Copyright © 2023 All rights reserved. | Privacy Policy | Terms of Service