Weighing, combining, and packaging cannabis is far more efficient and cost effective with automated batching.

Automated batching cannabis saves time and money for cultivators and cannabis processing, as it makes precise measurements, reduces product loss, and protects trichomes, thereby preserving potency. Automated batchers also ease the burden of labor costs, which helps cannabis cultivators and processors turn a bigger profit.

Simply put, batching systems automate the process of weighing, combining, and packaging cannabis flower to create a final product that’s ready for store shelves. Manual batching systems require multiple stations helmed by individual workers, and that process can be time-consuming and expensive in terms of labor costs.

By contrast, automated batching is quicker and more efficient, with the ability to handle a higher volume of product while also preserving the flower’s trichomes and the overall integrity of the cannabis buds.

What Is Automated Batching?

Simply put, batching systems automate the process of weighing, combining, and packaging cannabis flower to create a final product that’s ready for store shelves. Manual batching systems require multiple stations helmed by individual workers, and that process can be time-consuming and expensive in terms of labor costs.

By contrast, automated batching is quicker and more efficient, with the ability to handle a higher volume of product while also preserving the flower’s trichomes and the overall integrity of the cannabis buds.

Think about the processes involved in watering plants, one of the most fundamental steps in cultivating cannabis. The time-honored practice of hand-watering plants is fine for small-scale operations, like home grows. But as the cannabis industry expands and operations become more vast and sophisticated, large-scale cultivators have moved en masse to automated forms of irrigation in order to make their businesses more profitable and more sustainable.

In the same vein, running processing and packaging facilities without the help of automation is near impossible at this stage in the cannabis industry.

Automated cannabis batching pays for itself through:

- Better quality control

- Reduced labor costs

- Increased marketability

- Accelerated speed to market

- Reduces overpack and product loss

1. Scalability

Designing and building a cannabis processing facility is financially demanding. Cannabis cultivation and processing facilities require a variety of resources, including lighting, water, heating and cooling, and waste management, which makes it challenging to keep costs down and turn a profit.

An automated batching machine can adjust its performance in response to changes in your processing demands. When you first launch your facility, it makes sense to manage costs closely and grow slowly in ways that benefit your bottom line. But once your cannabis business takes off, you need the ability to quickly pivot to large-scale processing.

Automated batching allows for this approach, as it can be tuned to process more or less product depending on your needs. Manual batching, on the other hand, involves hiring or cutting staff, which is a far more complicated proposition.

What’s more, automated batching machinery can be enhanced as your facility grows. Downstream additions can include auto-jarring, capping, labeling, bagging, and more.

2. Preservation of Trichomes

Cannabis potency is a crucial selling point in this industry. Consumers expect the cannabis products they purchase to deliver a desired punch, and if your product falls short, it won’t last on dispensary shelves. That’s why you have to take good care of those precious trichomes.

Trichomes are the resin glands that decorate the surface of cannabis leaves and flower buds. A sticky and shiny coating, these protuberances contain cannabinoids that deliver the desired psychoactive effects. Destroy the trichomes and you destroy the cannabis itself, along with any potential profits.

Instead of relying on vibration to jostle and shake buds, automated batching equipment takes a more innovative approach, using gentle puffs of air to move buds along the product line while preserving trichomes. This results in higher end-potency, a more profitable market price, and a better consumer experience.

3. Higher Product Value

Consumers are interested in value. They want to purchase a cannabis project that satisfies their needs, but it has to justify the overall cost. Product value measures your product’s ability to meet and address the needs of your customer base. And with a higher product value, you can adjust pricing to be more profitable.

To achieve a higher product value, automated batching:

- Protects trichomes: Healthy trichomes equals a more potent product.

- Increases yield through decreased overpack: We weigh to 1/100 g every time.

- Keeps buds intact: A robust cluster of buds is important to consumers.

4. Time Saving and Labor Reducing

A higher product value may not be enough to help you hit your profit targets if your overhead expenses are out of whack, and labor is one of the most costly expenses incurred by any business.

There’s salary, of course, but there’s also healthcare, taxes, and potential worker compensation. While all businesses strive to afford these expenses, it isn’t always possible. That’s why investing in automated batching upfront is more cost-effective and has a bigger ROI than hiring a large team of manual batchers. Automated batching equipment far outpaces human workers, with the ability to process more than 20 batches of flower per minute. Human batchers simply can’t match that efficiency.

What’s more, automated batching equipment has the power to capture historical data. This means that each and every batch is recorded so that you can measure productivity. Automated batching does away with any guesswork in averaging out the amount of cannabis you process, instead, the equipment delivers actual numbers so that you can make informed decisions on labor and the amount of time each batch takes to process.

5. Packaging Consistency

Though the market is still relatively fresh, the traditional tenets that apply to mainstream products also apply to cannabis. And one of those tenets is the importance of packaging consistency! It doesn’t matter if you’re working with cannabis sativa or saltine crackers—packaging consistency contributes to a strong brand identity, which attracts consumers.

In using the batcher, you are able to control the consistency of your packaging so that the end consumer knows what they are getting, each and every time they reach for your product. Automating the batching process strengthens consistency without sacrificing control or quality.

Cannabis Industry Specific Batching Equipment

Because of its spotty legality over the years, cannabis cultivators and processors have had to make due with equipment designed for other industries. From irrigation systems to solvent extraction tanks and everything in between, purpose-built equipment is just now becoming the industry norm.

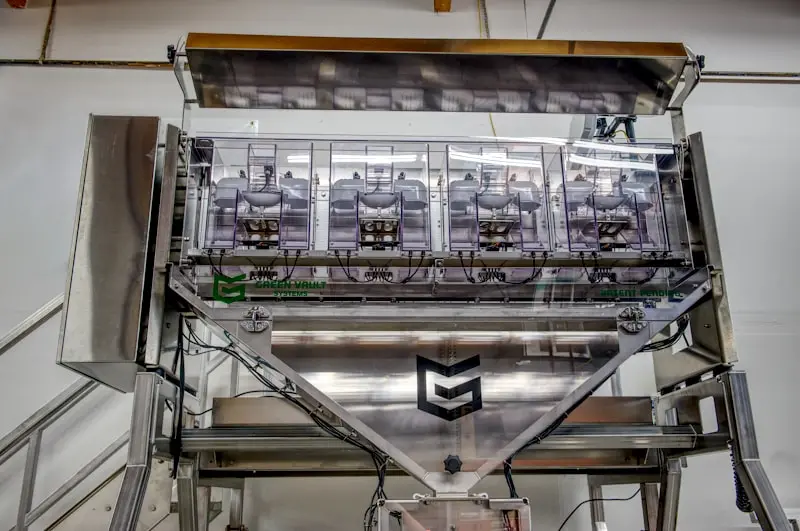

Designing machinery with cannabis batching in mind makes a huge difference, and when equipment such as the Precision Batcher knows it’s dealing with dried flower it can take into account the high value per gram and small weighing denominations.

Green Vault Systems is the ONLY manufacturer of cannabis industry-specific weighing and batching equipment. The machines we design, develop, and implement are not made for food and beverage, then retrofitted to handle cannabis.

That’s the old way of doing things.

Instead, we purpose build automated batching equipment and downstream equipment for the cannabis industry and only the cannabis industry.