Cannabis cultivators have historically been forced to use equipment meant for other industries.

Before legalization, cultivators used equipment made for other industries, including retail, food and beverage, agriculture, and pharmaceuticals. With modern-day cannabis cultivation equipment on the rise, cultivators now have access to soil nutrients, lighting, HVAC, harvesting tools, and packaging machinery specifically designed for the cannabis industry.

As public demand for legal cannabis grows, a collective move toward decriminalization has transformed cannabis from taboo “marijuana” into a valuable asset in a regulated industry. This shift in perspective doesn’t just include the plant. Those who consume cannabis for both medicinal and recreational purposes have shaken their unfair reputation as lazy stoners slacking on the fringes of society.

The evolution of cannabis has caused cultivators to dig deep in fields and indoor growing facilities and harvest crops that live up to the discriminating standards of modern-day consumers. And it hasn’t always been easy. Navigating the cannabis marketplace and producing buds that satisfy the public is downright difficult, especially when you’re forced to harvest and package flower using equipment designed for other industries.

Denny Smith, President of Green Vault Systems, notes that when the cannabis industry finally hit the map with recreational use in Colorado and Washington, the primary focus for startups was on the grow side of the process.

“Nutrients, lights, dirt—that sort of thing,” said Smith. “That meant that further processing (trimming, sorting, weighing, and packaging) was primarily performed by hand. Where it was being mechanized, processors used technology generally designed for heavy agriculture and food processing.”

However, cannabis cultivation requires tools specifically designed for the task at hand. And that task is to harvest and process this incredibly unique plant.

“Once the industry turned its attention to the retail side, the mood changed quickly,” Smith added. “Heavy competition in the retail space demanded that producers come with only the best quality products or risk being overlooked by those who did. It became apparent that purposefully designed equipment specifically for cannabis flower was needed to produce top-quality products."

Unfortunately, the history of cannabis cultivation is peppered with individuals retrofitting agricultural and even food service equipment. In this article, we’ll trace the timeline of cannabis cultivation equipment and examine that heavy-duty hardware that presents solutions to present-day cultivators.

Agricultural History and the Emergence of Cannabis Crops

Any discussion about the history of cannabis cultivation equipment must begin with a look at the early days of agricultural equipment, because they are, essentially, one in the same. For that, we are going way back—like, ridiculously back—in time. Here are a handful of highlights through agricultural history:

- Sumerian farmers use forked sticks as the first plows, dragging them through the dirt to create trenches where they could plant seeds.

475 BC

- Chinese agriculture takes off in the Hunan province with the development of an iron plow.

1702

- Jethro Tull of Great Britain (the actual guy, not the classic rock band) invents the seed drill and is perhaps the best-known inventor of a mechanical planter.

1797

- Charles Newbold patents the first cast iron plow in America.

Cannabis actually precedes all of those agricultural breakthroughs. The history of cannabis use dates back 12,000 years, placing the plant as one of humanity’s oldest cultivated crops. From those prehistoric origins, cannabis traveled to China, through Siberia, into the Middle East, and eventually arrived in America.

In each location, the plant was cultivated using primitive techniques like the ones described in the short timeline above.

Cannabis Cultivation Equipment

Though cannabis has literally thousands of years of history seeded around the world, it only recently sprouted into mainstream consumer marketplaces. As such, cannabis cultivation and processing equipment represents a sector that’s as niche as it gets.

That’s why professionals in the cannabis industry have had to make due with equipment “borrowed” from other industries. This approach has worked over the last decade or so, but it was never meant to be a permanent solution, and with legalization reaching more states—along with the strong possibility of federal legalization—the industry is primed for big changes.

As legalization takes hold, larger manufacturers and banks have grown less hesitant to fund cannabusiness endeavors once viewed as too risky. This progression has allowed modern entrepreneurs and marijuana machinery innovators to make it their mission to deploy purpose-built equipment for cannabis cultivation facilities.

Let’s take a look at some cannabis-specific cultivation and processing equipment that’s finally become available over the last few years.

Soil and Nutrients for Cannabis

Cannabis cultivators often find themselves acting like mad scientists in a laboratory, obsessed with achieving the perfect mix of macronutrients and micronutrients to satiate their prized plants. This is all because cannabis plants require a vital mix of nutritional elements in order to survive and thrive.

Cannabis requires three primary nutrients, or macronutrients, for optimal health:

- Nitrogen (N)

- Phosphorus (P)

- Potassium (K)

All plant food and fertilizer labels include the percentage of these three elements in numerical form, presented as N-P-K levels. Other macronutrients that help cannabis flourish include calcium (Ca), magnesium (Mg), and sulfur (S).

Micronutrients are equally important, but only tiny amounts are required and many, if not all, are readily available in potting soils without the need to add extra. These micronutrients, or trace elements, are:

- Boron (B)

- Chlorine (CI)

- Copper (Cu)

- Iron (Fe)

- Manganese (Mn)

- Molybdenum (Mo)

- Nickel (Ni)

- Zinc (Zn)

The agricultural industry is flush with pre-mixed soil products that include most, if not all, of these nutrients. And standard operating procedure for cannabis cultivators has always been to just use what’s available, even if it’s meant for tomato plants.

Companies such as Dyna–Gro, which initially produced plant food meant for orchids, now focus some of their efforts on cannabis propagation. And they aren’t the only ones. Companies across the board no longer hide the fact that their products offer premium nutrition for cannabis.

These manufacturers include: FoxFarm, General Hydroponics, and Botanicare KIND.

Cannabis Lighting

While the sun is the ultimate source of light, its propensity to set every evening and surrender to cloud cover makes it unreliable for cannabis cultivation. That’s why many professional cultivators have moved their operations indoors instead of outdoors or in greenhouses.

Indoor farming isn’t a modern-day phenomenon; in fact, some form of indoor farming has existed since what might be known as the first vertical farm, the Hanging Gardens of Babylon in the sixth century BC. Meanwhile, the first greenhouse was erected in Holland during the 1800s, where botanists mainly grew medicinal plants.

In those instances, the sun was the main source of light. Modern-day cannabis cultivators tend to lean into technology to make magic happen indoors. For many seasoned indoor cannabis cultivators, LED lights are the gold standard of artificial lighting. LEDs don’t just give growers complete control, with more accuracy and reliability than the sun could ever deliver, they’re also cost-effective and sustainable.

A report by the Cannabis Business Times demonstrates that LED usage for cannabis cultivation has lit up in recent years, with more than 45 percent of growers using it for all stages of plant growth. Not only that, about 60 percent of cultivators who don’t currently use LED lights said they will make the switch in the near future.

That’s almost entirely due to one major factor: availability. LED lighting arrangements for cannabis cultivation are more prevalent than ever, with manufacturers designing products specifically for the cannabis industry. While you can technically make due with any LED light, it’s best to go with the purpose-built product, such as lighting from Thrive Agritech and others.

HVAC Equipment

A crucial component to climate control across many industries, HVAC refers to heating, ventilation, and air conditioning. In the world of cannabis, HVAC (along with dehumidification) cleanses the grow room environment, keeping it temperature controlled, free of excess moisture, and well ventilated.

Opting for HVAC systems that were built for other industries is problematic for cannabis endeavors. This is mainly because most HVAC systems are energy intensive, significantly increasing costs to the overall operation. What’s more, industrial HVAC systems often create ultra-dry environments that are damaging to cannabis plants and they lack the flexibility needed to control air flow.

On the other hand, newly manufactured HVAC systems built for cannabis grow rooms can balance humidity levels and circulate cooling air as needed. One company in particular, Air2O, doesn’t shy away from displaying use cases for grow rooms alongside its prevalence in other spaces such as retail, food and beverage, and plastics.

Cannabis Harvesting

Throughout the history of the plant, cannabis cultivators harvested the crop with their bare hands and simple tools. Wielding a pair of gardening shears under the cover of darkness, they would take their plants from the field to the shed or garage. Growers would even water their cannabis gardens one plant at a time, moving slowly down the row before trimming buds with standard scissors.

That’s how it was done before legalization. Now, as we rocket through the 21st century, cannabis has become a commodity and times are changing.

The three harvesting steps that are changing the most are trimming, drying, and curing.

Trimming

Trimming is the crucial step that removes the bud from the plant, either through “wet” trimming or “dry” trimming. For wet trimming, cultivators cut the buds directly from the stalk immediately after harvesting. Dry trimming only occurs after the plant has hung in a drying room for an extended period of time.

For most commercial cultivators, the days of hand trimming are long gone. Machinery built for both wet and dry cannabis trimming is available from numerous dedicated manufacturers. Bud trimmers can vary considerably in size; some mammoth machines are able to trim several hundred pounds of cannabis in a single run.

Drying

When you opt for dry trimming, you need a sealed structure where you can store your buds until all the moisture has evaporated. Basements, tool sheds, and garages were fine for small-time growers in the 1960s, but modern-day cultivators have many more options in the era of legalization.

Mobile drying carts and drying racks give cultivators the chance to mass-dry plants, hanging them vertically with plenty of separation between the cannabis plants.

Curing

Curing is not drying, though many novice growers tend to confuse the two actions. Curing happens after the plant has already been trimmed and dried. When you cure cannabis, you store the previously dried buds in a way that encourages lasting moisture at the center of the bud to be redistributed to the outer layer.

Curing requires exacting temperature measurements for optimal results. Stored in airtight mason jars, buds must be cured in a dark place at a temperature around 70 degrees Fahrenheit and 60 to 65 percent humidity.

Cannabis Packaging

Plastic baggies of varying sizes don’t cut it with today’s cannabis consumers. Before legalization, it was perfectly normal to purchase nickel and dime bags of bud, but now, as cannabis enters the world of big business, cultivators and processors have to take competition into account. That means packaging cannabis in a way that protects the precious buds and sets you apart from competitors.

In addition, brands should understand that high-quality packaging reduces the risk of product loss and overpacking, which is increasingly important considering the volume of flower packaged today.

Materials

The sleek design of today’s packaging materials for cannabis resembles what you might see in high-end food products or cosmetics. Cannabis packaging material options include:

- Mylar bags

- Paper bags

- Polystyrene jars

- Glass jars

- Pop-top tubes

- Thumb click vials

As the industry continues to progress, more and more packaging options will enter the arena, each one vying for shelf space and attention from dispensary customers.

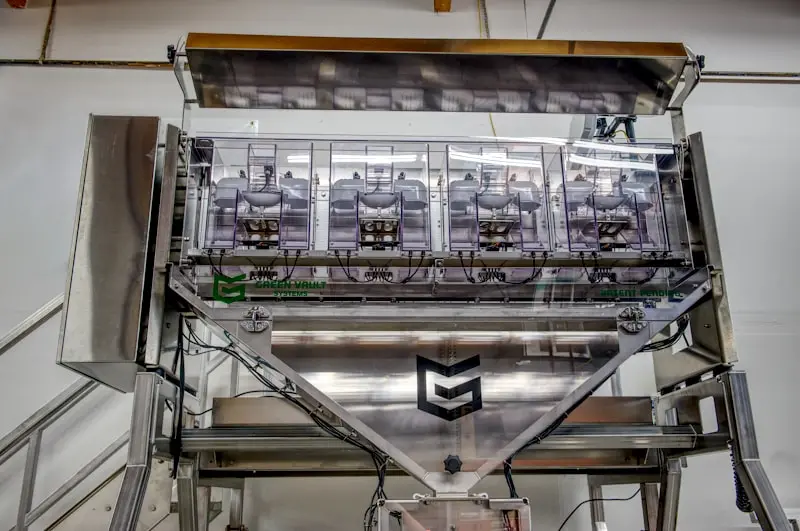

Green Vault Systems delivers full customization in its packaging materials. Available options include:

Jars (polystyrene and glass):

- Feeding and indexing

- Weight and content verification

- Cap and lid application

- Modified atmosphere

- Tamper-evident sealing

- Labeling

- Carton filling (robotics)

Bags (mylar and paper):

- Batch delivery systems

- Pouch filling

- Sealing

- Weight and content verification

- Printing

- Filling and forming

Machines

Back when cannabis was highly illegal, it wasn’t out of the ordinary for a bunch of buddies to gather around a dingy table in a dimly lit room and pack buds into bags. Back then, those buddies were the packaging machines. It wasn’t just illegal, it was also inefficient. Not only that, it created an environment where anyone could covertly pinch a nug or two for personal use.

In what has amounted to a cannabis industrial revolution, the last few years have seen the emergence of massive, automated machines meant to package cannabis at a clip, without sacrificing quality or packaging consistency, that would make old-school growers’ heads spin.