Does What You Package Impact How You Package?

As the cannabis industry continues to mature, the variety of packaging options has expanded, offering producers and consumers choices that align with their brand values, operational efficiencies, and customer preferences.

Journey with us as we explore the current landscape of cannabis packaging, highlighting the latest trends and emerging considerations, including the sustainability, durability, and perception of each packaging type. *read to the end to learn about one of our latest releases!*

Visual Presentation and Product Protection

Transparent Glass or Plastic Jars: The transparency of glass and plastic cannabis packaging containers allows customers to directly observe the quality of the product, ensuring they get what they expect. Additionally, jars provide robust protection for the contents, preserving terpenes and moisture through effective sealing.

Bags and Pouches: Premium bags, though less robust and more susceptible to crushing, can feature clear windows for displaying products and advanced materials to protect against terpene and moisture loss. However, these enhancements can raise costs and often do not match the biodegradability of other options. While cannabis packaging alternatives that support eco-conscious branding may be available, they do not provide the same level of protection as heavier plastics or glass.

Storage and Transport

Rigid Containers: Jars are indeed more robust but take up more space to store than bags. Additionally, they weigh more than bags, which results in higher transportation costs.

Bags: Pouches are easily compressible and lightweight, making them cost-effective for storage and transport.

Reusability and Sustainability:

Rigid Containers: These premium options are often repurposed, continuously reminding customers of your brand. Their durability and resealable nature make them a sustainable choice if consumers reuse them at home. Both glass and plastic can be made from repurposed materials and, in many cases, be recycled.

Bags and Pouches: While traditional plastic bags may end up in landfills, there are now eco-friendly options made from biodegradable materials or post-consumer recycled plastics.

Automation and Customization

Rigid Containers: Jars are easier to automate, especially if they have standard shapes with twist-on or press-on caps, leading to lower rejection rates during packaging processes. In addition, labeling can easily occur after the container has been filled.

Bags and Pouches: Bags tend to have higher rejection rates when automating and automated labeling generally needs to occur pre-fill. For both rigid containers and bags, custom shapes and designs might complicate automation even though they allow for distinctive branding opportunities.

Making the Right Choice

Choosing the right cannabis packaging involves considering factors such as sustainability, cost, consumer preference, and product integrity. At Green Vault Systems, we recognize that, historically, there has been no one-size-fits-all solution for packaging. UNTIL NOW

Many of our customers have found that different products may require different types of packaging, opting for the traditional elegance of glass jars, the versatility of plastic jars, or the modern efficiency of bags, depending on the specific needs of each product.

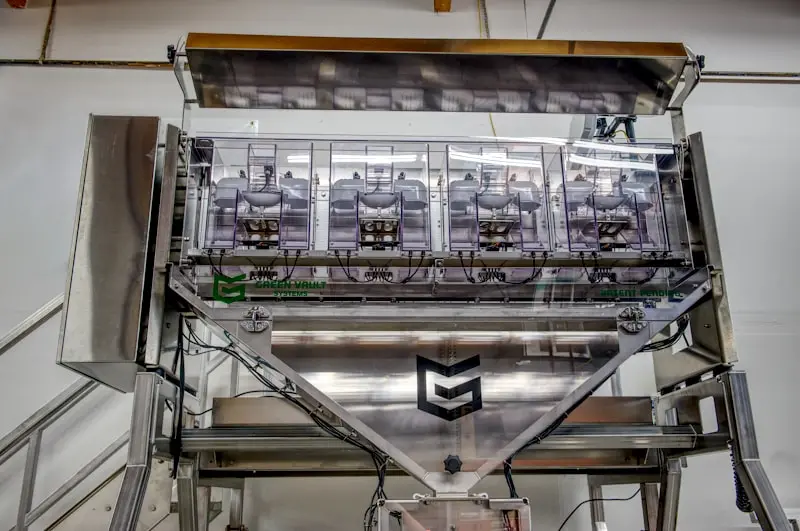

The Future of Packaging: Introducing the P-Flex

At Green Vault Systems, we understand the need for versatile and sustainable cannabis packaging solutions. That’s why we invented the P-Flex, a revolutionary bagging solution that allows you to switch from our automated jarring line to a bagging line in less than 5 minutes. As the industry continues to grow, so does the importance of making choices that benefit your business.

The P-Flex exemplifies our commitment to innovation, offering an adaptable solution without compromising the accuracy and reliability Green Vault Systems is known for.

Looking to learn more? Drop us a line on our contact page and we can discuss adding efficiencies to your operation.