Smart technologies allow you to fully automate nearly every aspect of cannabis cultivation.

Automation in cannabis cultivation and processing starts in the grow room, with automated lights, fertigation systems, and climate controls. Implemented automated systems reduce costs, streamline cultivation and extraction processes, and provide data-driven insights to optimize your operation.

The first humans to use watermills and windmills had no idea they were sparking the rise of automation. These early mills had the same purpose as today’s automated technologies: To improve efficiency, productivity, safety, and convenience.

In the modern era, automation has caused many industries to reconsider how they operate. From glass manufacturing and automotive assembly to electrical power generation and food and beverage processing, every industry imaginable now integrates some measure of automation.

And as technology marches on, more small companies and fledgling industries will gain access to automation.

“No-code and easier-to-use robotics will become more commonplace in 2023,” Jeff Burnstein, president of the Association for Advancing Automation, told Industry Week in a recent article. “Making robots easier to use, especially with no programming required, allows more companies to automate, especially small and medium-sized companies who are new to automation and don’t always have the in-house capabilities to handle complicated programming and set-up tasks.”

The cannabis industry is undergoing an automated technology revolution of its own. Sparked by expanding legalization and the brilliant minds of cannabis progenitors, automation is reshaping our industry as we speak.

In this article, we’ll plant the seeds of automation for beginners in the cannabis industry. You’ll learn why it’s so important, where it can be applied, and how smart automation is changing cannabis cultivation.

Why Is Automation Necessary for the Cannabis Industry?

The pioneers of the cannabis industry popped seeds using completely manual means. They cultivated on their knees, hands caked in dirt, shoulders scorched by the sun. Not only was it back-breaking labor, it was impossible to achieve commercial success without scores of workers on the clock.

Thanks to technological advancements, cannabis operations across the globe have evolved. Vertical integration is the name of the game, and cultivation managers can now automate practically every production process.

Automation can be applied to:

- Climate control

- Lighting

- Environmental monitoring

- Water treatment

- Irrigation and fertigation

- Transplanting

- Trimming

- Drying

- Grinding and processing

- Extraction

- Packaging

- Weighing

In each step of cultivation, automation can:

- Lower operating costs: Automation reduces labor costs, improves control over the growth environment, provides metrics in a software tracking system, and manages crops to increase efficiency and reduce costly waste.

- Streamline processes: Automation streamlines processes such as seed-to-sale tracking, Metrc (Marijuana Enforcement Tracking Reporting Compliance) reporting, and other compliance standards that vary by state.

- Increase efficiency: Sensors track every stage of a plant’s development, measuring all available data and providing recommendations to help farmers grow healthier plants more efficiently.

- Produce higher yields and better crop consistency: Automated systems pinpoint what’s working and what’s not working—from moisture levels to the overall environment. That knowledge facilitates plant consistency and greater yields.

- Allow for real-time visibility: Automated systems collect data with sensors and relay the information via the internet. This allows the grower to make remote changes to every aspect of the system, including climate control, moisture, and lighting.

What Rooms in a Cannabis Cultivation Facility Can Benefit From Automation?

Cannabis cultivators and processors are implementing the Internet of Things (IoT) and smart building technology into all aspects of design, and these advancements offer the extraordinary benefits of automation to every room in the cultivation facility.

For the most part, automation in the various rooms of a cultivation facility relates to climate control. The health and wellbeing of your indoor crop and final products depends on the climate in the rooms where your plants propagate, vegetate, flower, and dry.

In order to achieve homeostasis within your your cultivation facility, you must seek to automate all of the environmental aspects that contribute to changes in the climate, including:

- Lighting

- Temperature

- Humidity

- Airflow

- Carbon dioxide (CO2)

Here are the various rooms in a cultivation facility. It’s crucial you understand what occurs in these rooms and how controlling the climate protects your interests.

Mother Room

This is the genetic bank used for the preservation of cannabis clone varietals in case of pest or pathogen contamination in the propagation, vegetative, or flowering rooms.

Clone/Propagation Room

Housed here are genetically identical cuttings from the mother plants that are in the process of sprouting roots.

Vegetative Room

Cuttings that establish a healthy root system are moved to the veg room, where they are allowed to grow to about ¾ of their eventual size.

Flowering Room

Once fully realized in the veg room, plants are moved to the flowering room where it begins to develop flowers, which will eventually become the famous cannabis buds.

Drying and Curing Room

Fully matured plants are cut down and moved into a drying room and then a curing room. Here, special care is taken to preserve terpenes, with temperature and light exposure playing a crucial role in the development of cannabinoids.

Trimming Room

Trimming can take place before or after drying, largely depending on the cultivar. In this process, fan leaves are removed from in and around the cannabis buds.

Post-Processing Distillation Room

After the main solvent extraction of the biomass, the cannabis extract is distilled to remove residual solvents and further purify the product and its cannabinoids.

Infused Product Kitchen

After full completion of the extraction process, the cannabis concentrate is infused into a variety of final products, including edibles such as gummies, mints, and beverages.

Packaging Room

Packaging rooms are used to individually package dried cannabis flowers and extraction products for distribution and retail.

Shipping/Receiving Room

Often the final stop for cannabis products before they are sent out into the retail world, an optimal climate must be maintained in the shipping/receiving room.

Commercial cannabis cultivators cannot afford any miscalculations in these rooms, as anything less than an ideal climate can compromise your products and destroy any chance of turning a profit.

What Can You Automate in a Cannabis Cultivation?

Smart technologies such as automation amount to more than merely presetting lights to flick on at a certain time or gearing an irrigation system to water your plants while you’re away. It’s also about data collection, analysis, discovery, and action, all of which inspire massive returns in the cannabis industry.

And though the cannabis industry is well established, it is relatively new to automation and, in general, the Internet of Things (IoT). Consumer demand is rising. Legalization is spreading throughout the country. Implementing IoT technology such as automation streamlines processes, provides insight and control, and gives cultivators the tools needed to navigate obstacles and sustain growth.

But what does automation throughout the facility actually look like? Let’s take a tour of a cultivation operation and see where automation fits.

Lights

For many seasoned pros of the indoor cannabis cultivation collective, automated LED lights are the be-all and end-all of artificial lighting. That’s because LEDs give the grower the power to control what they’re doing much more precisely, while also being sustainable and cost effective.

The automation of LED systems is perhaps the biggest reason why cultivations are flocking to this style of lighting. LED light automation boasts control presets dictating various details for all stages of growth, including:

- Lighting scheduling

- Dimming

- Spectral tuning controls

HVAC and CO2

HVAC refers to heating, ventilation, and air conditioning, and it’s essential to air quality control in all industries, including cannabis cultivation. Meanwhile, properly calibrated CO2 levels trigger photosynthesis in plants, which helps the plants produce energy and growth.

An integrated HVAC and CO2 control system can be automated to maintain optimal airflow and CO2 level at all times. And with IoT technologies, you can view grow room conditions from anywhere with an internet connection.

Fertigation (Fertilization and Irrigation)

Your cannabis plants are thirsty for water and nutrients—why not combine both needs into one automated solution? Fertigation is the application of fertilizers or nutrients into the irrigation network, where crucial plant nutrients are dissolved into the actual watering system. An automated fertigation system uses wireless sensors to determine the temperature, electrical conductivity (EC), and moisture level at the root zone of the plant.

Automated fertigation integrates seamlessly into a cannabis facility’s larger environmental control system. From there, fertigation can be monitored and managed from a user interface that controls all processes of your grow operation.

Temperature and Humidity Control

Rooms for various stages of growth require temperature and humidity levels to be just right; the temp needs to be warm enough so the plants don’t freeze but cool enough so they don’t fry. For temperatures, the sweet spot is generally between 65 to 85 degrees Fahrenheit. For humidity, you should look for a range of 40-70 percent relative humidity to keep mold at bay and influence transpiration rates.

Automated temperature and humidity systems allow for remote and on-site monitoring. You can actively “crop-steer” your plants with direct temperature and humidity controls, ensuring you always have a comprehensive visualization of climate data support so that you can make informed decisions based on automated analysis.

Ventilation

An automated ventilation system should mimic the processes of the natural world. When cannabis is grown outdoors, the wind strengthens the stalks and the overall plant structure. Indoor cannabis, on the other hand, can grow weak if it never gets the chance to stand up to the wind.

Automating the airflow in your facility helps the cannabis biomass by:

- Strengthening plant stems

- Reducing instances of mold and powdery mildew

- Keeping pests from making a home on plants

- Facilitating temperature and humidity homeostasis

Trimming

In the early days of cannabis facility automation, the mere thought of an “automated trimming system” would make cultivators extremely nervous. They imagined machines indiscriminately clawing and tearing at buds, damaging delicate trichomes and destroying strains. Thankfully, technology has advanced and so have automated trimmers.

Today’s automated trimming systems are able to “see” flowers, leaves, trichomes, and petioles like human trimmers. High-end automated trimmers feature data-driven, AI technology that scans the entire cannabis plant down to the individual trichome, which guarantees precision trimming to maximize yield and profit.

Drying and Curing

The primitive process of drying and curing cannabis once took place over the course of a few weeks, often in a darkened shed with a hands-on approach. Trimmings were hung to dry, then the buds were sealed in air-tight containers that required periodical burping.

The latest in automated drying and curing technology features sealed chambers, laminar airflow dynamics, terpene capture capability, UV-C anti-microbial airflow mitigation systems, a one-step dry and cure solution, and more. What’s more, automated drying and curing systems even boast cloud-based controls, as well as on-plant moisture sensors to provide the most precise and consistent method for drying and curing in the cannabis industry.

Extraction

Closed-loop hydrocarbon extraction is a cannabis extraction method that utilizes an extractor vessel completely closed to the outside atmosphere. It uses hydrocarbon solvents, such as butane or propane, or CO2. These are highly volatile chemicals. As such, it’s always a great idea to amp-up the safety factor in extraction any chance you get.

An automated extraction system removes human workers from the danger zone, but the benefits of automated extraction extend well beyond safety. Extraction systems that utilize automated controls reduce operator error and remove the need for mechanical valves. These advanced systems cut down on costs and reduce the time it takes to load and unload extraction vessels, thereby increasing throughput.

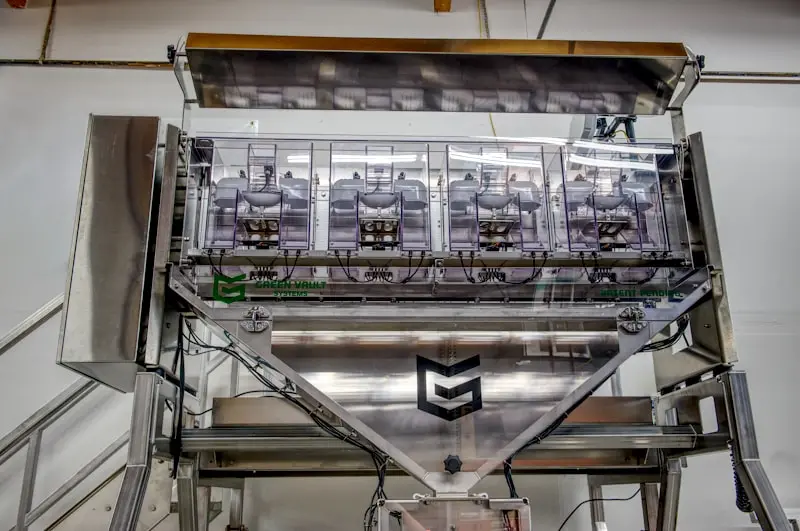

Packaging and Weighing

Manually operated packaging and weighing systems can create impossible bottlenecks in the cannabis industry. Automating this final step in the cannabis cultivation facility ensures your numbers are accurate, your product is safe from human error, and your brand enjoys the consistency that customers expect from a cannabis product.

The Green Vault Systems Precision Batcher automatically weighs out batches, checks finished batch weight for inconsistencies, and dispenses the product into all manner of packages, including jars, pop tops, and bags.

Takeaway

Automating your cannabis plants’ processing cycle with smart technologies provides you with a daily record of how your products are reacting—in real time—to nutrient feed, LED light spectrum, CO2, the environmental conditions of your grow space, and more. Automation truly gives you the advantage of unimpeded insight into optimal conditions for business growth in the cannabis industry.