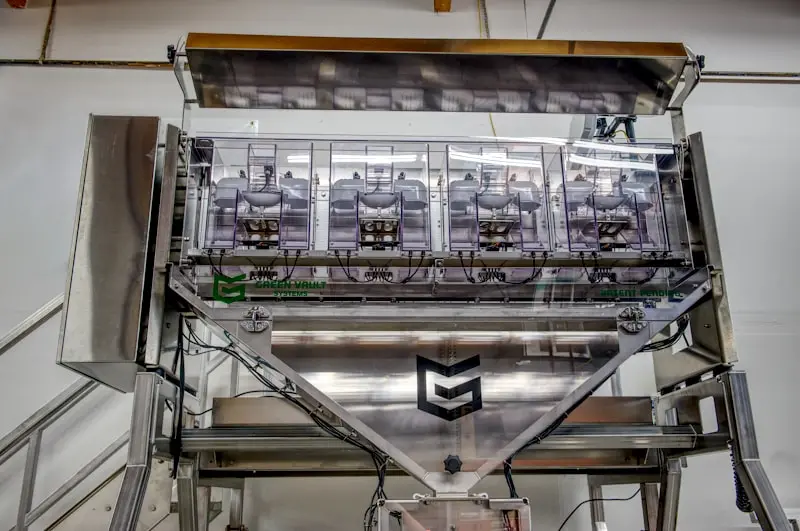

Optimize Efficiency & Cost Savings with Green Vault Systems' Precision Batcher Data

At Green Vault Systems, we engineer our equipment to handle cannabis flowers delicately and vibration-free, ensuring the highest level of accuracy and efficiency.

Did you also know that the GVS Precision Batcher provides data and reports with performance metrics and insight into production trends to help you optimize throughput? Analyzing detailed metrics like production rates, overpack percentages, average weighments per run, reject rates, operator efficiencies, and machine run time will offer valuable insights into overall productivity.

You can generate summaries of each production run and export them as CSV, Excel, or Numbers worksheets for further evaluation.

Come with us as we delve deeper into specific strategies and best practices for leveraging this wealth of information to identify areas of improvement and optimize efficiency within your production processes.

Identifying Strain Types for Accurate Parameters

Before diving into the data specifics of the reports, we recommend identifying the type of flower for each program run, whether by strain or phenotype, ie. dense or wispy.

This will allow you to see patterns across different strains helping you to refine your programs. This targeted approach can lead to more efficient and effective batching processes, minimizing waste and maximizing yield.

Key Metrics

Having clarity on key metrics is essential for effectively evaluating and improving production processes. By focusing on the following key areas, facilities can gain a comprehensive understanding of their production performance and identify opportunities for improvement.

- Feed Efficiency

- Catch Efficiency

- Reject Rates

- Average Pieces (Bins) Per Batch

Feed and Catch Efficiencies

These first two areas are easy to diagnose, either the rates are high, or they aren’t. Ideally, both the Feed and the Catch should be in the 90th percentile for optimum efficiency.

The feed controls the speed but if the machine is not being emptied quick enough it will slow down the process.

The Feed and the Catch are very interdependent; even if the feed is above 90% but the batches are not being cleared, the batcher will not be able to drop batches to the check-weighers, thus decreasing overall machine performance.

Conversely, if the operator is not feeding quickly, the Catch rate may appear high, but that may be because the batches are arriving slowly.

You may notice, that as your Feed rate improves the hand Catch numbers may come down a little. This is common. However, the more we can keep both numbers in the 90th percentile, the better the overall machine efficiency.

And – remember, the Catch number is relative to the Feed number. So, if the Feed is at 20% but the Catch is at 90%, the overall machine efficiency will be at 18%, and if the Feed is at 85% and the Catch is at 60%, the overall efficiency of the Batcher will be at 51%.

Therefore, efforts should be made to optimize both Feed and Catch rates. The addition of the Precision Infeed and our automated jar and bagging lines ensure consistent and streamlined processing, ultimately improving overall machine efficiency.

Reject Rates

Typically, we aim for reject rates below 8% and ideally strive for 5% or under.

Several factors can contribute to higher reject rates, including scale calibration errors, incorrect parameter settings, or even airflow issues within the batching system.

Identifying the root causes of elevated reject rates is essential for implementing targeted solutions.

Calibrating the Scales

Ensuring accurate scale calibration is crucial for maintaining precision and minimizing reject rates in batching processes. Here are some important tips and considerations for calibrating scales effectively:

- Settling Weight: Before initiating calibration, it’s essential to ensure that the weight on the scale is settled. Taking an extra moment to allow the weight to stabilize helps ensure correct calibration and prevents inaccuracies.

- Minimize Movement: Movement around the machine during calibration can affect precision. To minimize potential disruptions, it’s advisable to perform calibration during quiet times when there is minimal activity around the machine. This helps maintain a stable environment conducive to accurate calibration.

- Avoid Airflow Interference: Airflow can also impact the precision of scale calibration and machine operation. It’s important to ensure that air is not blowing in the direction of the Batcher both during calibration and while the machine is running. Airflow interference can cause fluctuations in weight readings and affect the overall performance of the batching system.

- Temperature Fluctuations: If the packaging room has a swing in temperature greater than +/- 10 degrees F since the last calibration, the scales will not perform optimally and should be recalibrated.

Parameters

Adjusting parameters is a key aspect of optimizing batching processes for efficiency and accuracy. Here are some considerations and strategies for effectively managing parameters:

- Target Weights: Keeping the targets slightly tighter while allowing ample space for outliers at the checkweights can help improve the precision of the batching process while reducing reject rates.

- Check Weights: When setting the Check Weights give ample space on the minimums and maximums relative to the target weights.

All Bins Full

“All Bins Full” situation indicates that the Batcher is unable to find a suitable combination of flower to meet the specified parameters for a batch. Here’s how this scenario is typically addressed:

In response to an “All Bins Full” condition, half of the holding cells will automatically empty, diverting the contents to be rejected. The operator will then need to refill the emptied bins to ensure a continuous flow of materials for batching.

While encountering “All Bins Full” situations occasionally is not uncommon during a shift, consistent or frequent occurrences may indicate underlying issues that need to be addressed.

Often an “All Bins Full” situation can be attributed to a discrepancy between the specified parameters and the actual input material.

Examples:

- 3.5g Batch Run with the inclusion of a maximum piece count of 6

In this scenario, the parameters set a maximum limit of 6 pieces of flower for a 3.5g batch. However, if each piece of flower being fed into the system consistently weighs only 0.5g, then attempting to create a batch with 6 pieces (6 x 0.5g = 3g) will result in a batch that falls short of the target weight.

- The “Star”piece scenario asks for at least one 0.8g piece in each batch.

In the “star piece” scenario, if the input material does not include any 0.8g pieces the system will be unable to find a batch that meets the requirements, and an “All Bins Full’ will be activated.

Addressing such “math” issues involves ensuring alignment between the parameters set for batch creation and the characteristics of the input materials. This may require adjusting parameters such as batch size, weight thresholds, or tolerances.

Mis-Feeds

In addition to the speed of the feed being important, the timing is also critical.

It’s essential to synchronize the feeding process with system signals, such as indicator lights or sensors, to ensure that material is introduced into bins at the appropriate time.

In other words, if a flower is fed when the light is not green, it will be rejected. In addition, in cases where multiple flowers are fed simultaneously, ensuring proper registration of each flower’s weight is critical. If multiple flowers are “trickled”, the weight of the last flowers may not register, resulting in rejected batches.

The Precision Infeed plays a crucial role in mitigating mis-feeds and addressing issues like the “trickle effect” in batching.

While the Smart Feed System reduces labor by removing the need for an additional person, the Precision Infeed independently alleviates these issues whether or not it is integrated with the Smart Feed System.

Average Pieces / Bins per Batch:

Maintaining an average of 3 to 4 bins per batch is a key strategy for optimizing overall machine performance. Providing operators with real-time feedback on the weight range of each feed is invaluable for controlling how many bins may be needed to make a batch.

By actively analyzing the last 20 feeds, the Batcher can assess whether the individual weighments fall within the appropriate range and alert the operator to any deviations. This live feedback enables operators to make immediate adjustments as needed.

Comprehensive Support: Free Lifetime Customer Service

Green Vault Systems is committed to ensuring customer satisfaction and ongoing success.

Regular follow-ups and data reviews are critical for helping our customers maximize the value of their investment and optimize machine performance over time.

By proactively engaging with customers, reviewing operational data, and troubleshooting any concerns, your GVS support team plays a crucial role in ensuring that you continue to achieve optimal results from your equipment.