What One Case Study Can Teach the Entire Industry

When a company like Phat Panda—one of the most respected names in cannabis—makes a major shift in their automation strategy, it’s worth paying attention. Their story isn’t just a feel-good success case—it’s a blueprint for how to scale smarter, protect margins, and maintain craft status while meeting massive demand.

Follow us as we break down key lessons from Phat Panda’s transition to Green Vault Systems (GVS) automation, and show how other cannabis operators can replicate their results.

Challenge #1: Scaling Without Compromise

As cannabis companies grow, so do the challenges: higher volume, tighter compliance, complex SKUs, and rising labor costs. Phat Panda, once a 30-person team, now employs over 550 and has a robust multi-state presence.

They needed automation that could:

- Keep pace with demand

- Protect delicate flower quality

- Cut costs without cutting corners

But their old equipment couldn’t keep up. Repairs were constant, accuracy was questionable, and overpacking was bleeding profits.

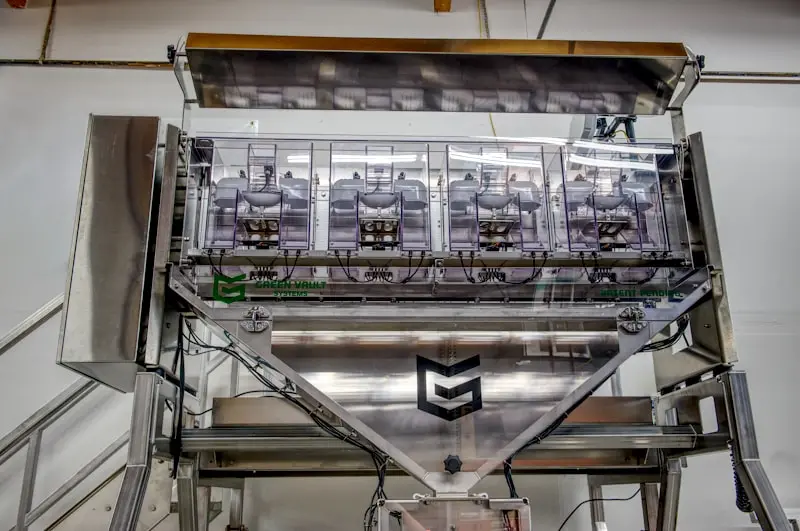

Solution: Equipment Built for Cannabis (Not Candy)

Green Vault Systems provided Phat Panda with our Precision Batcher, a high-speed, ultra-accurate system powered by our patented AirKush™ technology—designed specifically for cannabis, not retrofitted from other industries.

Here’s what happened next:

- Phat Panda jumped from 200–300 packages/hour to 600+

- Operators needed less training time

- Overpack dropped significantly, protecting margins

- The system was gentle enough to preserve trichomes and terpene integrity

The difference? True cannabis-first design.

Key Insight: Automation Should Pay You Back

Every cannabis operator asks, “What’s the cost of automation?” But the better question is, what’s the return?

In Phat Panda’s case, the Precision Batcher didn’t just save time—it made them money by:

- Reducing product loss

- Cutting labor hours

- Increasing output per square foot

- Preventing downtime with better support and reliability

With compact equipment and seamless bag or jar changeover, the same team was able to do more—with better quality control.

Bonus Benefit: Better People, Better Partnerships

Phat Panda didn’t just switch because of specs. They switched because the GVS team showed up, asked the right questions, and delivered a tailored solution with free lifetime support.

“They’re responsive, knowledgeable, and always available,” said Tyler Miller, Director of Facilities at Phat Panda. “That’s not something we experienced with our previous vendors.”

Actionable Takeaways for Cannabis Producers

Want to apply Phat Panda’s lessons to your own operation? Start by asking:

- Are you overpacking without realizing it?

- Is your current system built for cannabis—or just adapted?

- Can your equipment scale with your business, without retraining your team every 3 months?

- Are you spending time fixing breakdowns—or building your brand?

The difference between stress and scalability starts with asking the right questions—and choosing a partner who knows this space inside and out.

Final Thought: Don’t Scale Alone

If you’re growing fast and want to preserve the craft that got you here, let’s talk. We’ll review your current setup, identify pain points, and show you how we can make your automation process work harder (and smarter) than ever before. Reach out TODAY!